电话:0512-81639966

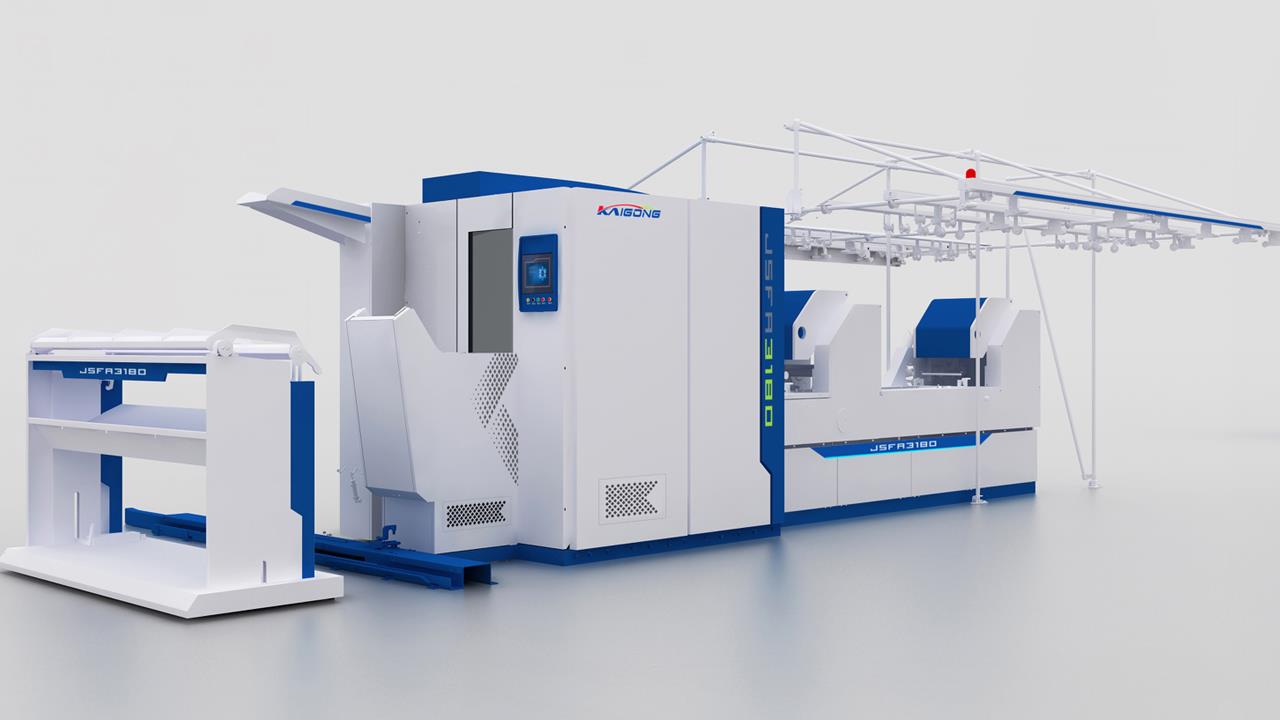

JSFA3180型条并卷机

作者:凯宫机械 发布时间:2023-11-13 16:46

JSFA3180型条并卷机特点说明

JSFA3180 Sliver Lap Winder Machine Features Description

(1)、平带式柔性卷绕系统

Flat belt flexible winding system

开发平带式柔性卷绕机构,经过紧压罗拉的纤维层在平带与筒管之间摩擦力的带动下卷绕。平带柔性约束卷绕,280°大角度包覆式面接触小卷,提高纤维层之间的清晰度、成卷速度。

The flat belt flexible winding mechanism is developed, which is driven by the friction between the flat belt and the bobbin through the fiber layer of the tight roller. Flat tape flexible binding winding, 280 ° large angle wrapped surface contact small coil, improve the clarity between fiber layers, winding speed.

(2)、卷绕在线控制调节装置

Winding on line control and adjustment device

开发平带卷绕在线控制调节装置,能够对高速运动平带的运行状态进行即时控制与调整,保证正常运行及生产质量。

The development of flat belt winding on-line control and adjustment device can control and adjust the running state of high-speed flat belt in real time to ensure the normal operation and production quality.

(3)、卷绕压力在线控制

On line control of winding pressure

新型的棉卷定位纤维层卷绕筒管中心不变,从小卷到满卷纤维卷密度保持一致,纤维卷在整个工作过程中不粘连,不松动,改善重量不匀率,小卷米重量不匀率≤0.5%。

The new type of cotton coil positioning fiber layer winding bobbin center is unchanged, the density of the fiber coil is consistent from small coil to full coil, the fiber coil does not adhere and loosen in the whole working process, and the weight unevenness is improved, and the weight unevenness of small coil is less than 0.5%.

(4)、新式抓管机构

New type of pipe grasping mechanism

优化设计筒管微调装置对抓管机构位置的调节和紧固,送管机构与夹盘中心等机构的准确配合。避免因气压波动或异常等原因出现的握持力下降,筒管脱落现象。

Optimize the design of bobbin fine adjustment device, adjust and fasten the position of the pipe grabbing mechanism, and accurately coordinate the pipe feeding mechanism with the chuck center and other mechanisms. Avoid the drop of holding force and bobbin falling off due to pressure fluctuation or abnormality.

(5)、棉层控制机构

Cotton layer control mechanism

采用双气缸单项控制稳定性好,纤维卷达到定长两侧边向中心方向折起,使纤维卷顺利地卷绕到筒管上,退绕时快速地找到棉层的头端,实现生产中自动完成,提高运转效率。

Double air cylinder single control is adopted, the stability is good, both sides of the fiber coil reach the fixed length and fold to the center direction, so that the fiber coil can be smoothly wound to the bobbin, and the head end of the cotton layer can be quickly found when unwinding, so as to realize the automatic completion in production and improve the operation efficiency.

(6)、智能筒管自动喂给机构

Intelligent bobbin automatic feeding mechanism

具有筒管自动喂给和存储两个功能,采用横向排列筒管的方式,充分利用设备导轨和本体间的距离自动连续喂给,机构稳定,筒管放置轻松便捷。

It has two functions of automatic feeding and storage of bobbins. It adopts the way of transverse arrangement of bobbins and makes full use of the distance between the guide rail and the main body of the equipment to feed automatically and continuously. The mechanism is stable and the placement of bobbins is easy and convenient.

(7)、机身结构优化设计

Optimization design of fuselage structure

优化设计机身减小车架的体积,使设备的占地面积由传统条并卷联合机占地面积约40 m2(600 mm条桶)减少到28 m2,方便了工人操作,节约厂房用地,降低综合成本。

By optimizing the design of the fuselage and reducing the volume of the frame, the floor area of the equipment is reduced from 40 m2 (600 mm barrel) to 28 m2, which facilitates the operation of workers, saves the land of the plant and reduces the comprehensive cost.

(8)、牵伸机构传动优化

Transmission optimization of drafting mechanism

牵伸系统借鉴精梳机采用平皮带传动,取消工艺齿轮箱、万向联轴器等环节,牵伸座、主架墙板、平带等零件均采用精梳机零部件,工艺更改灵活方便,且皮带、皮辊支架、轴承等易耗品均与精梳机通用,可减小备件库存,简化操作难度。

Drawing system uses flat belt drive for reference of comber, cancels process gear box, universal coupling and other links, adopts comber parts for drawing seat, main frame wallboard, flat belt and other parts, so process change is flexible and convenient, and belt, roller bracket, bearing and other consumables are common with comber, which can reduce spare parts inventory and simplify operation difficulty.

(9)、控制程序的开发

Development of control program

根据控制点、形式、纤维卷成型要求等,优化整机控制程序,实现操作简单、维护方便,具备人性化的数据统计、故障信息反馈及局域网信息传输功能。小卷成型所需的压力曲线调整升级,只需轻按控制面板上的按钮即可,人机界面友好。

According to the control point, form and fiber coil forming requirements, the control program of the whole machine is optimized to realize simple operation and convenient maintenance, with humanized data statistics, fault information feedback and LAN information transmission functions. To adjust and upgrade the pressure curve for small coil forming, just press the button on the control panel, and the man-machine interface is friendly.

主要工艺参数

Main technical data

(1)卷绕速度:

Winding speed

设计速度 230 m/min

Design Rate: 230 m/min

工艺速度 Max. 210 m/min

Running speed: Max. 210 m/min

(2)小卷:Lap

棉卷定量 60-80 g/m

Batt weight 60-80g/m

满卷重量 Max. 25 kg

Lap weight Max. 25kg

满卷直径 Max. 580 mm

Lap diameter Max. 580mm

棉卷宽度 300 mm

Lap width 300mm

(3)预并条:

Pre-drawing

并合数 22-28根

No. of feed slivers 22-28

棉条定量 3.7-6.0 ktex(18.5-30 g/5m)

Weight of sliver 3.7-6.0 ktex(18.5-30 g/5m)

条桶直径 600/1000 mm

Can Diameter 600/1000 mm

(4)筒管:

Spool

纵向宽度 300 mm

Longitudinal width 300 mm

外部直径 200 mm

Outside diameter 200 mm

重量 2 kg

Weight 2 kg

(5)棉卷产量:

Cotton roll production

棉卷定量80 g/m时 Max. 590 kg/h

While batt weight 80 g/m: Max. 590 kg/h

棉卷定量75 g/m时 Max. 550 kg/h

While batt weight 75 g/m Max. 550 kg/h

棉卷定量70 g/m时 Max. 515 kg/h

While batt weight 75 g/m Max. 515 kg/h

棉卷定量65 g/m时 Max. 475 kg/h

While batt weight 75 g/m Max. 475 kg/h

棉卷定量60 g/m时 Max. 440 kg/h

While batt weight 75 g/m Max. 440 kg/h

(6)牵伸:

Drafting

牵伸头数 2个

No. of drafting heads: 2

牵伸型式 三上三下牵伸

Drafting system: 3-over-3 roller drafting

加压型式 气缸气动加压

Pressure type: pneumatic weighting

(7)牵伸倍数:

Drafting times

GV:总牵伸 1.395-2.427倍

Total drafting 1.395-2.427

HV:主牵伸 1.314-2.285倍

Main drafting 1.314-2.285

VV:后区牵伸 1.032-1.112倍

Back zone drafting 1.032-1.112

(8)牵伸隔距:

Drafting gauge:

主牵伸隔距(钳口间)L1: 42-60 mm

Main draft gauge (between jaws) L1: 42-60 mm

HVD:前区罗拉座间隔距HVD=L1-42 mm

HVD: The distance between the front roller seat HVD=L1-42 mm

后区牵伸隔距(钳口间)L2: 44-63 mm

Rear zone draft gauge (between jaws) L2: 44-63 mm

VVD:后区罗拉座间隔距VVD=L2-44 mm

VVD: the distance between the rear roller seat VVD=L2-44 mm

(9)牵伸张力:

Drafting tension:

棉条桶与牵伸系统间 -1-1.1 %

Between sliver bucket and drafting system -1-1.1%

牵伸系统与紧压罗拉间 -0.6-1.3 %

Between the drafting system and the compression roller -0.6-1.3%

紧压罗拉之间 3 %

Between the press rollers 3%

紧压罗拉与卷绕筒管间 1-5 %

Between press roller and spool 1-5 %

(10)棉卷卷绕:罗拉控制的皮带“Ω型”包覆卷绕

Cotton roll winding: belt "Ω-type" covered winding controlled by roller

(11)牵伸皮辊: 3 9 mm(外径)X300 mm(长度),85(硬度)

Drafting roller: 39 mm (outer diameter) X300 mm (length), 85 (hardness)

(12)全机重量: 约3.9 Ton

Machine weight: 3.9 Ton

(13)额定功率: 11 kW

Rated power: 11 kW

(14)运行功率: 约4.5 kW

Running power : 4 .5 kW

(15)压缩空气耗气量:约14.5 Nm3/h(7 bar 标准大气压力)

Compressed air consumption: about 14.5 Nm3/h (7 bar standard atmospheric pressure)

(16)吸风负压: min. 1000 Pa

Suction negative pressure: min. 1000 Pa

(17)吸风耗气量: 0.8 m3/s

Suction air consumption: 0.8 m3/s

(18)吸风管直径: 300 mm

Diameter of suction pipe: 300 mm

(19)基础承载能力: 10600 N/m2

Foundation bearing capacity: 10600 N/m2

下一篇:JSFA588精梳机